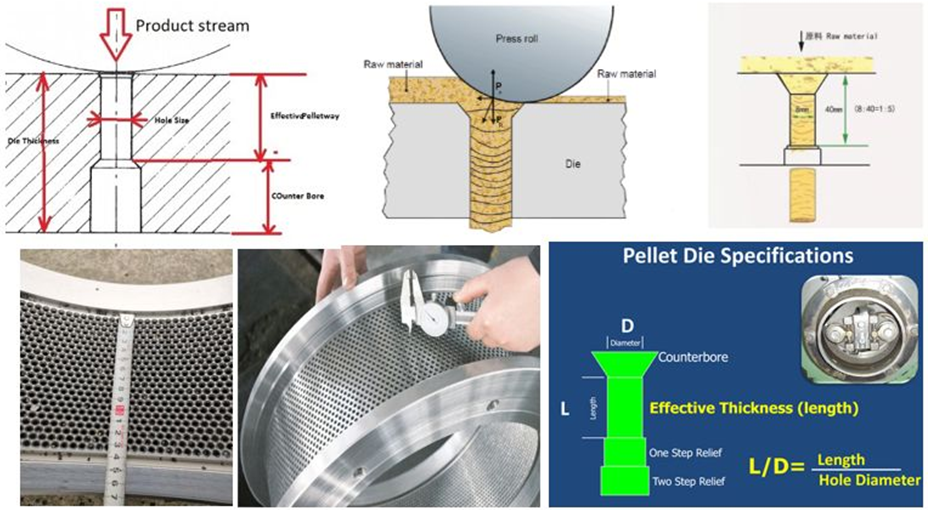

How to calculate the compression ratio & performances for ring die?

1- calculate the compression.

Die specifications:

Examples: 1

Die specifications:

ø 3.5 x ET 50 mm (THK 65 mm)

65 – 15 = 50mm (die thickness 65 and 15 mm counter drilling, leaving an effective pelleting canal length of 50 mm) For broiler feed: pellet Ø 3.5 mm

Calculated compression ratio: effective canal length / pellet Ø = 50 / 3.5 = = ratio 1:14.3

The compression ratio is low and expected to producing low PDI from this spec.

Examples: 2

Die specifications:

Hole Ø: 4 mm x ET 65 mm (THK 75 mm)

75 – 10 = 65mm (die thickness 75 and 10 mm counter drilling, leaving an effective pelleting canal length of 65 mm) For Layer feed: pellet Ø 4 mm

Calculated compression ratio: 65/4 = = ratio 1:16.25

The compression ratio is okay and expected to producing good PDI from this spec and increase the capacity.

Examples: 3

Hole Ø: 3 mm x ET 65 mm (THK 75 mm)

75 – 15 = 60 mm (die thickness 75 and 15mm counter drilling, leaving an effective pelleting canal length of 60 mm) For broiler feed: pellet Ø 3 mm

Calculated compression ratio: 60/3 = ratio 1:20

The compression ratio is very good and expected to producing high PDI from this spec and low capacity

|