What effect does the outer surface structure of the pressure roller have on production?

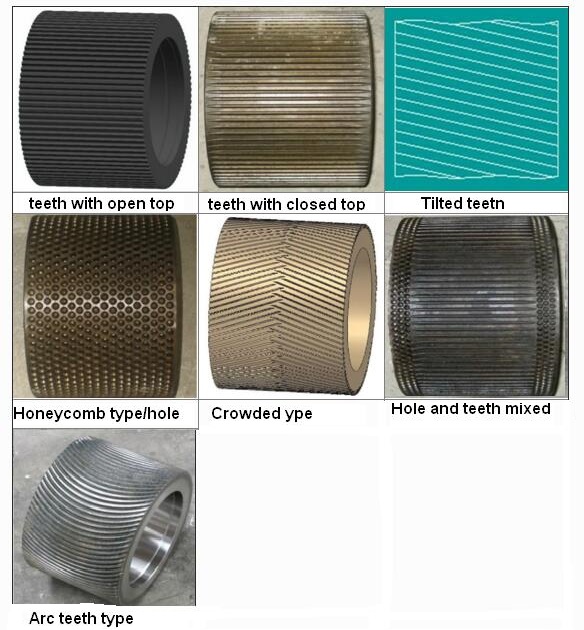

The structure of the outer surface of the pressure roller mainly includes the tooth groove type, the tooth groove type with sealing edge and the honeycomb type.

The tooth groove type pressure roller has good coil performance and is commonly used in livestock and poultry feed plants. However, because the feed slides in the tooth groove, the pressure roller and ring die wear unevenly, and they wear at both ends of the pressure roller and ring die. For a long time, the two ends of the ring die are difficult to discharge, and the produced particles are shorter than the middle part of the ring die.

The tooth groove type pressure roller with sealing edge is mainly suitable for the production of aquatic material. The aquatic material is easy to slide when squeezed. Because the tooth groove is sealed on both sides, it is not easy to slide to both sides when the feed is squeezed. It is more uniform, and the wear of the pressure roller and the ring die is also more uniform, so that the length of the produced particles is also more consistent. |